Stone Cottage Retrofit: A Silent Ground Source Heat Pump Solution in Norfolk

A master heat engineer case study

Helping YOU find good heating engineers. We share case studies from engineers in the Guild of Master Heat Engineers to help people find top installers, help gas and oil engineers increase their knowledge around heat pumps, and provide a solution for third-sector professionals to understand the industry better.

Installio powers the The BetaTeach newsletter.

Overview

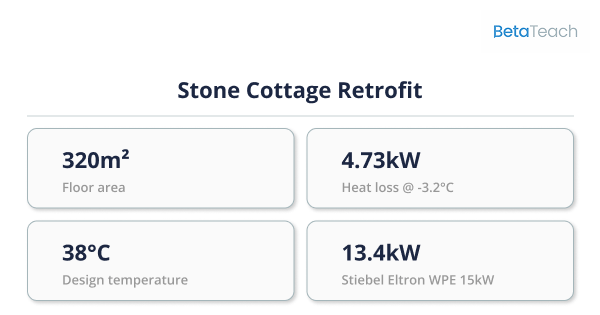

A stone cottage, originally built in 1820, underwent a meticulous two-year renovation, doubling its size to 320 square meters. Nestled in a remote location, far from any light or noise pollution, the property serves as a serene retreat for a high-profile client from the movie/film industry. To complement its tranquil surroundings, the project required a heating solution that not only matched the peace and quiet but also supported the specific needs of a film professional seeking a distraction-free environment. This case study highlights the transition from a noisy, inefficient oil boiler to a state-of-the-art Stiebel Eltron ground source heat pump system. Designed to address the challenges of a high water table, this advanced solution ensures precise comfort while remaining nearly silent, making it the ideal choice for a space where every detail counts.

An expert installation of a Stiebel Eltron WPE-I H Premium 15kW ground source heat pump (GSHP) alongside a dedicated domestic hot water cylinder. The plant room demonstrates precision engineering with high-grade copper pipework designed to optimise the coefficient of performance (COP) for residential heating. This setup represents a benchmark for renewable integration, delivering sustainable low-carbon hot water and space heating via a high-efficiency system.

Master Heat Engineer

Steve Webster from EGE Energy About EGE Energy Ltd EGE Energy Ltd is a family-run business based in Norfolk, specialising in renewable energy solutions and energy-efficient heating for domestic and commercial customers. With over 40 years of experience in plumbing and heating, they provide the latest sustainable technologies to help you save energy and reduce costs. Experienced & Reliable: Over 1000 heat pump installations since 2005, with most of their business coming from customer referrals. |  Master Heat Engineers Steve Webster overseeing the technical specifications of a high-efficiency heating installation. A regular guest on the award winning BetaTalk podcast, Steve is widely recognised for his precision engineering and commitment to best practices in the UK renewable sector. His involvement ensures that complex systems, such as the Stiebel Eltron ground source unit featured in this project are optimised for maximum seasonal performance and hydraulic efficiency. |

Key Specifications

Heat Pump: Stiebel Eltron WPE 15kWBuilding Load: 13.4 kW @ -3.2°C

Hot Water Storage: 300l Cylinder

System Layout: Open Loop

Heat Distribution: UFH

Ground Collector: 800 meters

The Challenge: Silent Operation in a Zero-Noise Environment

The primary challenge was the property’s unique acoustic requirement. The original oil boiler was audible from a significant distance, and while modern air source units are quieter, the client required a near-silent solution to preserve the site’s natural tranquility. Geographically, the installation was complicated by a very high water table. This necessitated laying the ground collector in partially flooded trenches, a difficult task for the installation team.

Groundworks phase for residential ground source heat pump system, featuring a Sany tracked excavator excavating trenches for the external collector loops. High-density polyethylene (HDPE) ground loop piping is prepared on-site for installation into the specified trench depth. This critical stage of a GSHP project ensures the necessary sub-surface heat exchange capacity to support the Stiebel Eltron heating system, highlighting the scale of civil engineering required for sustainable geothermal energy extraction.

System Design

The engineering team specified a Stiebel Eltron WPE 15kW ground source heat pump to meet the 13.4 kW heat loss at design outside temperature (DOT). The external array consists of an 800m ground collector. Despite the difficulty of the flooded trenches, the high moisture content in the soil proved to be a technical asset; the increased thermal conductivity allowed for a high energy yield, which enabled a reduction in the overall array size.

The internal system is designed for maximum simplicity and efficiency:

Emitters: Underfloor heating (UFH) installed on both ground and first floors.

Configuration: A pure open-circuit design using Stiebel weather compensation to modulate flow temperatures based on external conditions.

DHW: A 300L cylinder serves the domestic hot water requirements.

Final connection of the horizontal ground loop array into a central geothermal collector manifold. This stage involves the fusion of mechanical coupling of multiple HDPE pipe circuits from the trenches into a single distribution hub, which then carries the thermal energy to the Stiebel Eltron heat pump. Proper manifold positioning and trench bedding are essential to ensure balanced flow rates across the ground array, protecting the long-term hydraulic integrity and heat extraction efficiency of the ground source system.

Performance & Results

By utilising weather compensation and an open-loop design, the system maintains a consistent 38°C flow temperature at design outdoor temperature (DOT). The ground source solution successfully delivered the requested "silent" operation, removing all mechanical noise from the external environment.

To ensure long-term reliability, the system is integrated with remote online monitoring. This allows the engineers to track performance and fine-tune settings as homeowner usage patterns emerge. This proactive monitoring ensures any potential issues are identified and resolved before the occupants become aware of them.

Estimated Heat Loss (kW) at Various Outside Temperatures

Temp | kJ/Sec | Temp | kJ/Sec |

|---|---|---|---|

-3°C | 13.4 | 6°C | 8.4 |

-1°C | 12.3 | 10°C | 6.1 |

0°C | 11.7 | 13°C | 4.5 |

3°C | 10 | 16°C | 2.8 |

Thanks to the Patrons

The Guild of Master Heat Engineers is supported by our Patrons.

Learn more about our Patrons here.

BetaTalk Podcast

Join me for an insightful conversation with Steve Webster, a seasoned professional in the heat pump industry and a distinguished figure in the Guild of Master Heat Engineers, in this Betatalk Podcast episode. Steve sits down with industry legend John Cantor, whose book on domestic heat pumps remains my personal favourite and is often considered the first of its kind. Steve shares how he discovered John’s groundbreaking work when he first started exploring heat pumps, and the mutual respect between these two pioneers is truly inspiring. If you’re keen to dive into the roots of heat pump technology and the experts who shaped its evolution, this episode is a must-listen.

Closing Thoughts

Reflecting on the evolution of our industry, it is impossible not to focus on Steve Webster. Steve is the epitome of what the Guild of Master Heat Engineers stands for: a commitment to peer learning and the peer assessment that I founded BetaTeach to champion. His journey is a masterclass in resilience, from coming back to life from a cardiac event to overcoming aggressive throat cancer with remarkable strength. Steve’s career, which began on survey ships for the original Norway-to-UK gas pipes, has evolved into a legacy of mentorship.

He is truly a "Master’s master," having mentored some of the professionals within the Guild, like John Wood and Damon Blackmore. While Steve has slowed down slightly, he remains a sharp force in the industry, supported by a talented business partner (Scott) who now handles some of the admin and a remarkable wife, Wendy, whose support has been nothing short of inspirational. As my favourite heat pump engineer and a dear friend, Steve remains a cornerstone of the UK’s renewable sector. His story reminds us that the best engineering isn't just about pipework; it’s about the character and the people behind the craft.

Have a great rest of the week everyone.

Nathan

Subscribe to get more newsletters like this, if you haven’t already.