Vaillant Heat Pump Achieves SCOP 4.2 in North Yorkshire: Open-Loop Simplicity for a 1900 Era Farmhouse Retrofit

A master heat engineer case study

Helping YOU find good heating engineers. We share case studies from engineers in the Guild of Master Heat Engineers to help people find top installers, help gas and oil engineers increase their knowledge around heat pumps, and provide a solution for third-sector professionals to understand the industry better.

Installio powers the The BetaTeach newsletter.

Overview

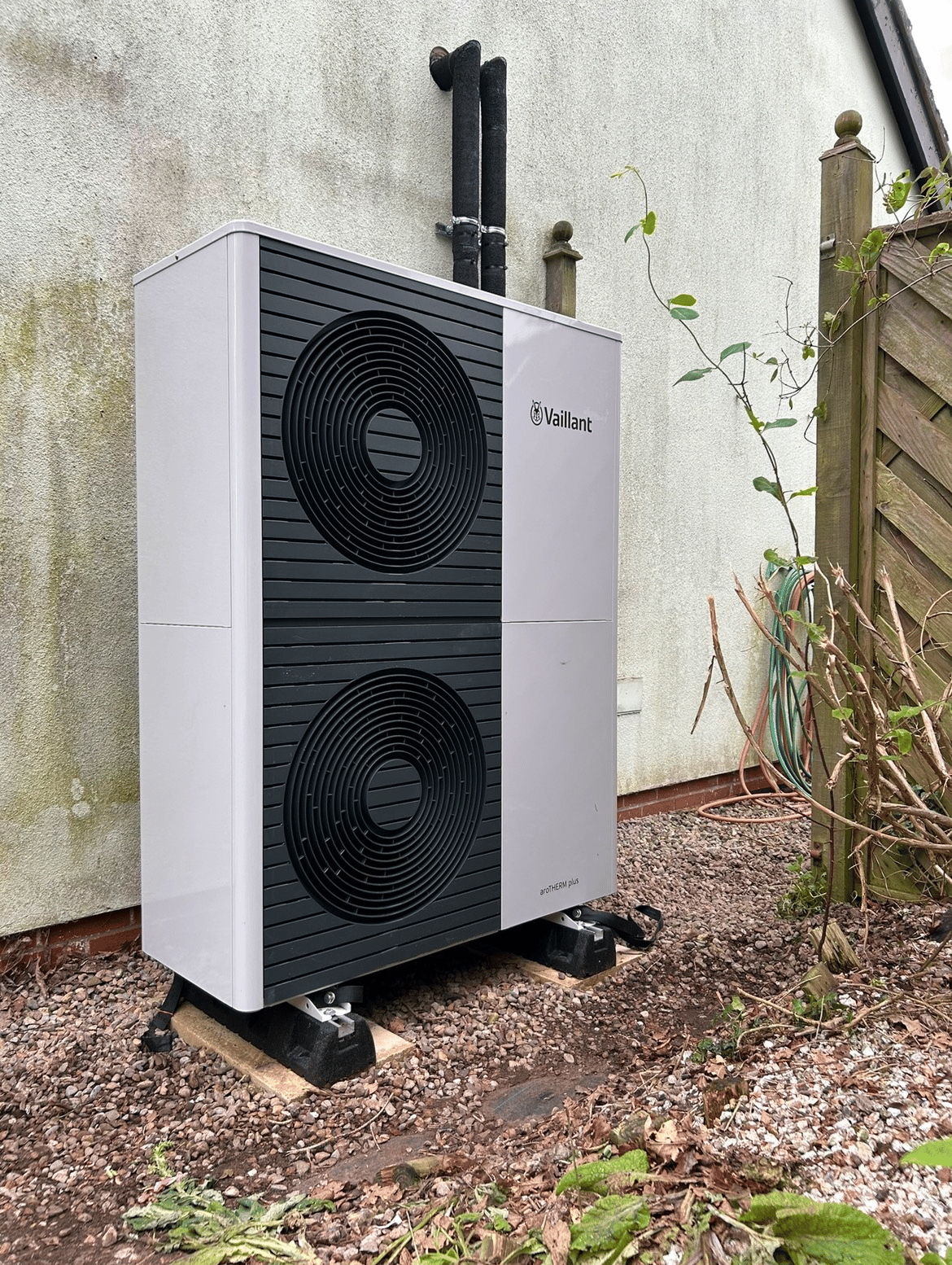

A Vaillant aroTHERM plus 12 kW heat pump was commissioned for a rural property near York, North Yorkshire — a traditional farmhouse dating back to 1900 with three later extensions (1945, 1967, and 1988). The system design integrated a mix of radiators and two underfloor heating areas: a combined UFH/radiator layout on the ground floor and radiator-only on the first floor.

To keep the installation simple and efficient, the system was set up as a direct open-loop arrangement with no buffers, hydraulic separation, or mixing valves. The entire design was calculated to deliver the required output at exceptionally low flow temperatures, ensuring the property could consistently hold 20 °C across all parts of the building despite the varied construction standards of each extension.

After 12 months of monitoring via OpenEnergyMonitor, the system has delivered stable performance at a Seasonal Coefficient of Performance (SCOP) of around 4.2. Interestingly, the homeowner — a lead data scientist working with Octopus — has at times pushed the system harder than the design intent during periods of cheaper electricity tariffs. Even so, the heat pump has continued to perform reliably, and with plans to adhere strictly to design parameters this year, the long-term efficiency figures are expected to improve further. You can also see this reflected on OEM — over the past 90 days, it has been sitting at around 600% efficiency.

Master Heat Engineers

|

Key Specifications

Heat Pump: Vaillant aroTHERM plus, 12 kW output

Building Load: Calculated heat demand of 11.2 kW at design temperature of –3.7 °C

Hot Water Storage: Heat Geek Super Cylinder (Newark), 300 litres

System Layout: Open-loop configuration

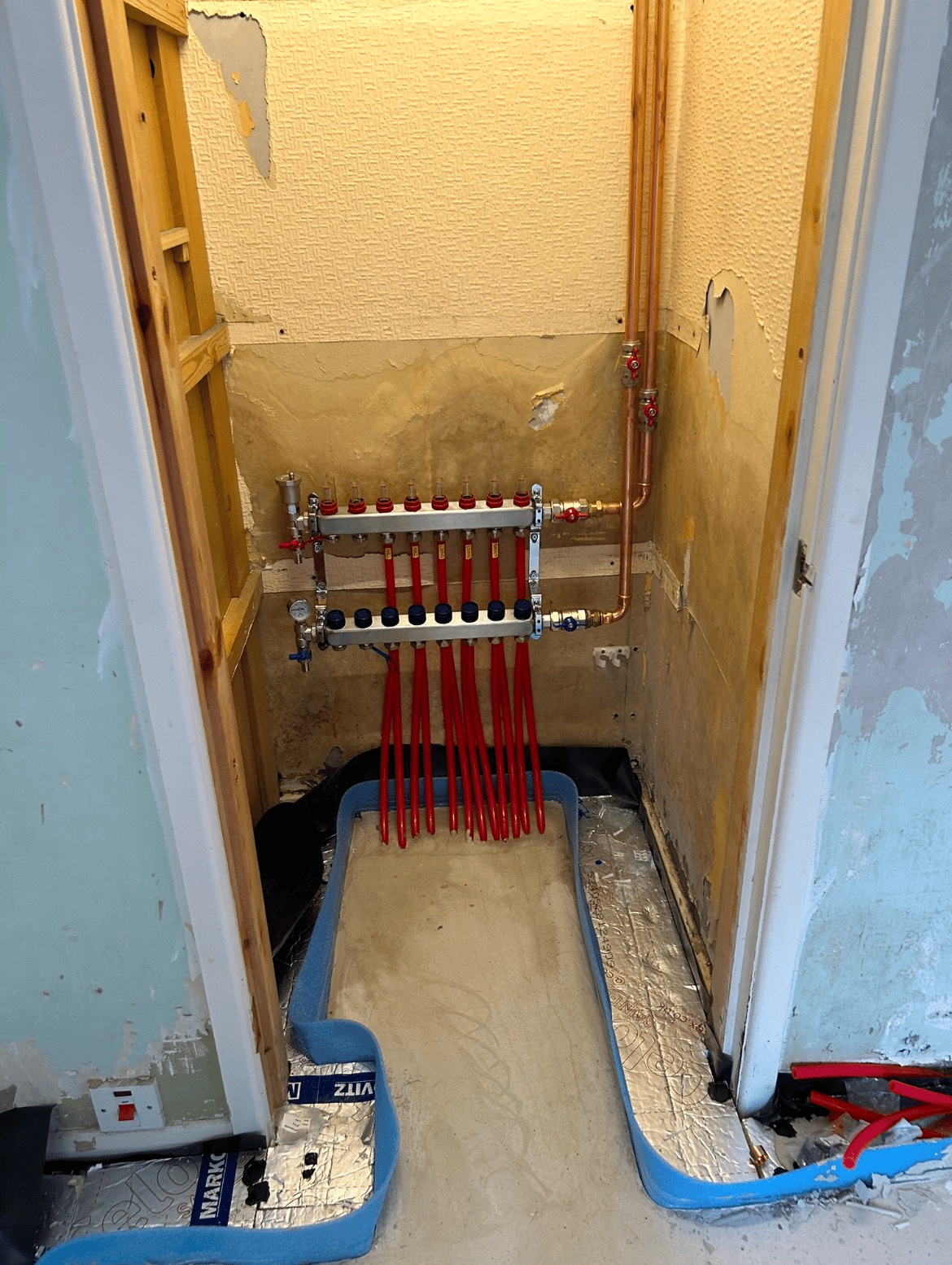

Heat Distribution: Underfloor heating and radiators on the ground floor; radiators to first floor

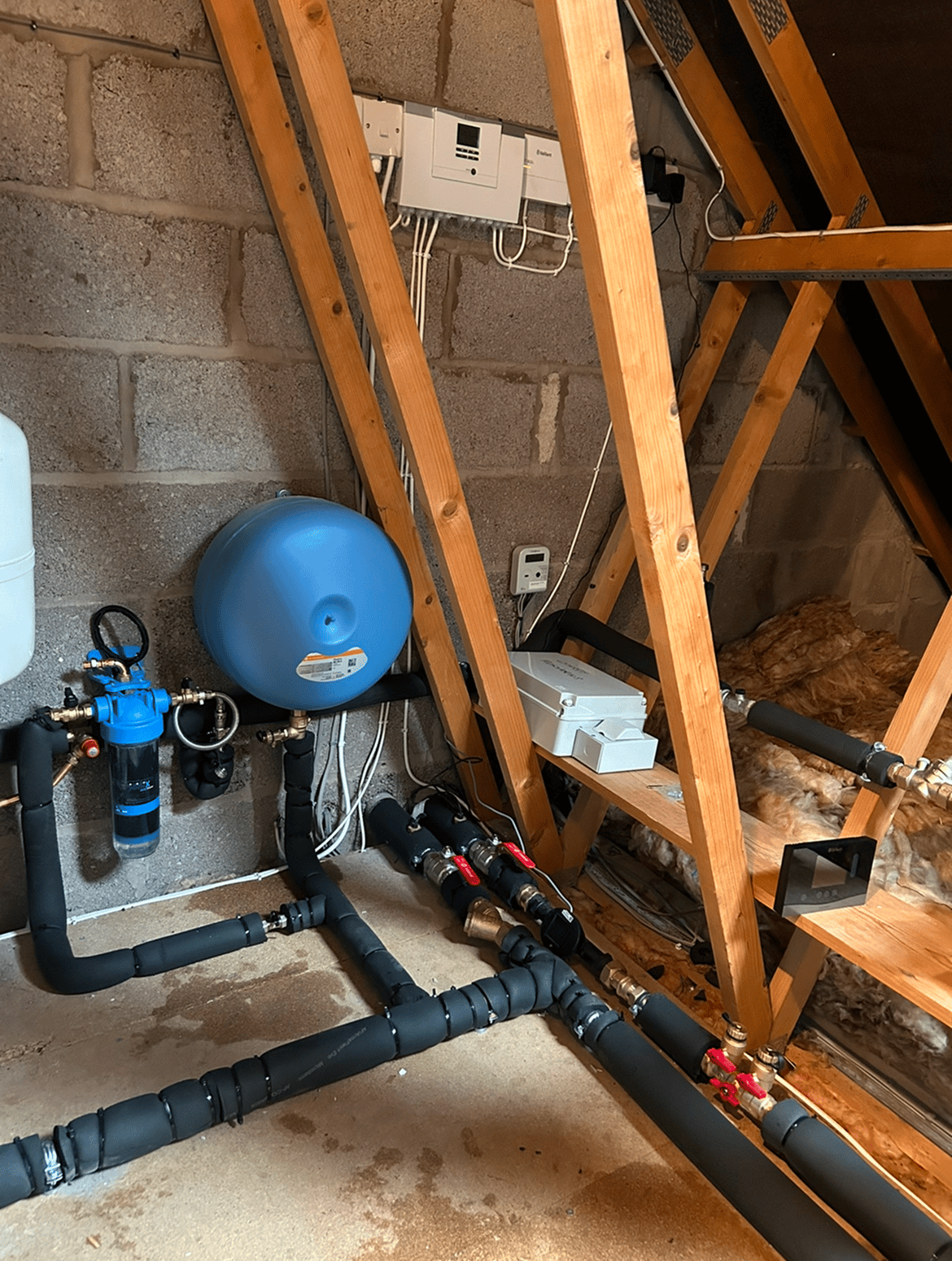

Primary Pipework: 35 mm copper with Primary Pro insulation

Control Valve: ESBE VRG133 diverter

Water Quality: Filled and treated in line with VDI standards

Maintenance: Throughflush MiniX top-up unit installed

The Challenge: Blending Old and New into One Efficient System

This 1900 farmhouse, with minimal insulation but solid 18-inch stone walls and a concrete floor, had the added complexity of three extensions — each built to different standards in line with the regulations of their time. The task was to integrate all of this fabric with a mix of traditional radiators and underfloor heating into an open-loop system, designed to maintain a steady 20°C throughout the property with just a 40°C flow temperature.

Conventional thinking would have carved the house into multiple zones, adding layers of complication. Instead, by approaching the design differently, the system achieved a 4.2 SCOP over the last year — and that's despite the client occasionally running it outside of the original design parameters.

System Design

This installation was engineered to operate as a fully open-loop system with a maximum flow temperature of just 40°C.

Through precise calculations on the underfloor heating (UFH) pipework and by replacing every radiator in the property with correctly sized alternatives, we created a design that removed the need for blending valves, pumps, or additional controls on the UFH manifolds.

The system runs directly from the Vaillant air source heat pump, paired with a Heat Geek Super Cylinder by Newark. The cylinder's oversized 6m² heat exchange coil maximises heat transfer efficiency, allowing the system to deliver exceptional performance.

As a result, we are consistently achieving a SCOP of around 4.9 for hot water production.

|  |

Performance and Results

The heating system is currently operating with the Vaillant 12 kW aroTHERM Plus air-source heat pump set to inactive mode. This is when the system runs purely on weather compensation. It modulates the flow temperature continuously to keep the building stable, without "room thermostat-style" stop–start operation.

Heating Distribution: The underfloor heating (UFH) circuits and radiators were carefully and manually balanced to ensure even heat distribution throughout the property.

Domestic Hot Water (DHW): Set point of 50 °C with a 5 °C offset, ensuring reliable hot water supply while maintaining efficiency.

Flow Temperature: Heating flow limited to 40 °C, keeping the system within low-temperature operation for maximum efficiency.

Internal Comfort Temperature: Maintained at 20 °C, with room conditions fluctuating between 19–20 °C. A 2 °C setback strategy is used between the target and setback temperatures to further enhance energy savings while preserving comfort.

Estimated Heat Loss (kW) at Various Outside Temperatures

Temp | kJ/Sec | Temp | kJ/Sec |

|---|---|---|---|

-3°C | 10.9 | 6°C | 6.6 |

-1°C | 9.9 | 10°C | 4.7 |

0°C | 9.5 | 13°C | 3.3 |

3°C | 8 | 16°C | 1.9 |

The Weekly Engineer Directory

Find a Master near you:

Engineer | County |

|---|---|

Angus, Scotland | |

London | |

Kent |

Thanks to the Patrons

The Guild of Master Heat Engineers is supported by our Patrons.

Learn more about our Patrons here.

Podcast

Solaris Energy feature in this weeks directory for the Guild of Master Heat Engineers. Listen to Nathan chat with their director Dan.

The important topic of water quality comes up and Solaris Energy use VDI 2035 methods rather than a chemical inhibitor approach.

Dan is on the installer working group at MCS and gives insight into this process.

The episode also discusses heat pump controls and how Dan and Solaris Energy have become involved with the heat pump manufacturer Kronoterm.

Closing Thoughts

I really enjoyed this case study from John. John epitomises an engineer who has took ownership of his own learning. He is constantly active in peer to peer learning and even had my favourite engineer, Steve Webster from EGE Energy come visit him when he first started to consider heat pump installations. I love the fact this install is for one of Octopus's lead data scientists so there is great opportunity for wider learning within the sector.

You will notice John used VDI 2035 methods for water quality e.g. protecting the system from corrosion. We will be discussing this method, as opposed to dosing with chemical inhibitors, in further newsletters. There is a major issue with overdosing with the use of chemicals and this had led to the break down of components.

Well done John.

Have a great week everyone.

Nathan

Subscribe to get more newsletters like this, if you haven’t already.