High-Efficiency Air Source Heat Pump Installation with Open-Loop Design: Ware, Hertfordshire

A master heat engineer case study

Welcome to the BetaTeach newsletter. We share case studies from engineers in the Guild of Master Heat Engineers to help consumers find top installers, inspire gas and oil engineers to expand their skills, and provide reliable knowledge for third-sector professionals.

Installio powers the The BetaTeach newsletter.

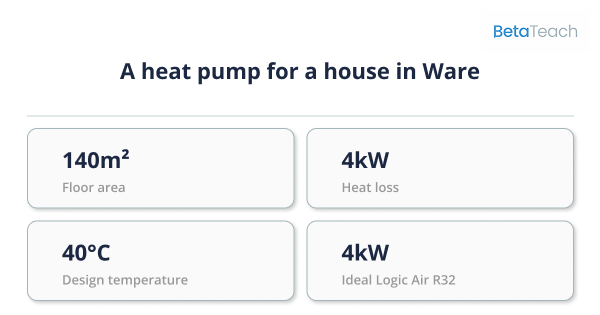

Overview

An Ideal Logic Air R32 heat pump was installed in a four bedroom detached property in Ware, Hertfordshire, featuring underfloor heating (UFH) downstairs and radiators upstairs. The design centered on simplifying the system into a single, open-loop zone by eliminating unnecessary components like buffer tanks and blending valves. This careful balancing of emitters allowed the system to operate at an extremely low flow temperature.

The installation achieved an independently verified Seasonal Coefficient of Performance (SCOP) of 4.7 after nearly a year of operation.

Master Heat Engineers

Alex Winters from Libtek. |  |

Key Specifications

Heat Pump 4kW Ideal Logic Air R32

Estimated Calculated Heat Loss 4kW at a Design Outside Temperature (DOT) of -3°C

Hot Water Cylinder Heat Geek Super Cylinder (Newark) 200l

Heating Distribution Underfloor Heating (Downstairs) & Radiators (Upstairs)

System Design Open-loop, bufferless system

Maximum Flow Temp 40°C at DOT

External Pipe Insulation Primary Pro

The Challenge: Simplifying the Hybrid Emitter System

The primary challenge was integrating the two different types of emitters - low-temperature underfloor heating (UFH) and traditional radiators - into a single, highly efficient zone. Conventional wisdom would dictate the use of secondary components (pumps, blending valves) to manage the flow temperature split between the two zones, reducing overall system efficiency and increasing complexity.

Design and Installation Innovations

The installer engineered a solution to run the entire system as a single zone at a maximum flow temperature of 40°C at DOT. This was achieved by calculating the UFH pipe sizing and floor coverings, and replacing only four existing radiators upstairs with appropriately sized alternatives. This approach eliminated the need for a UFH pump, blending valve, and TRVs.

The installer opted to try the Ideal Logic Air R32, noting the impressive controls package and excellent support from the manufacturer's representatives (James Smith and technical engineer Stuart Wilson).

To maximise hot water efficiency, the installer substituted the manufacturer’s cylinder for the Heat Geek Super Cylinder by Newark. This choice, thanks to its large 6m2 heat exchange coil, results in DHW cycles achieving a COP over 5 when ambient temperatures are around 15°C. System protection was ensured using the Inta HP filter and Inta antifreeze valve and primary pro pipe installation.

Primary Pro Pipe insulation & seal and bond.

Performance and Results

The heating strategy was set to pure weather compensation, allowing the heat pump to modulate flow temperatures based on external conditions. The UFH and radiators were manually balanced to ensure even heat distribution across the property.

Domestic hot water was set to 48°C with a 2°C offset, resulting in a maximum flow temperature of 50°C. The cylinder requires only a single heating cycle at 4 am daily to meet the family's needs.

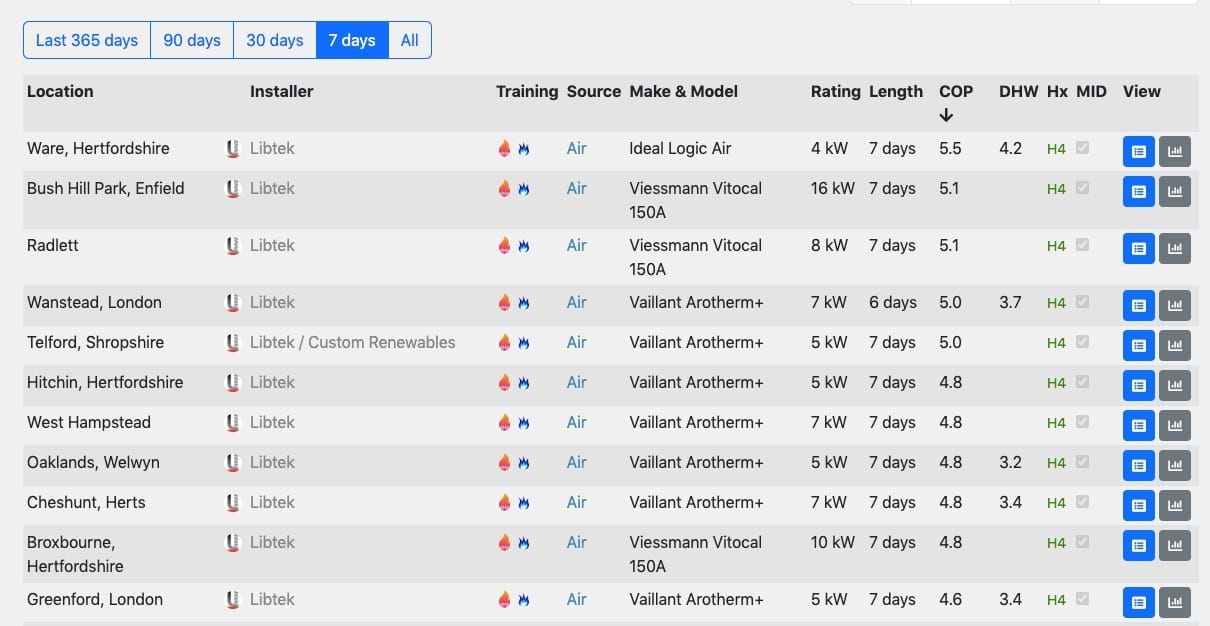

The true system performance has been tracked using an Open Energy Monitor third-party kit, which confirms the high Seasonal COPs of 4.7 after nearly a year of operation. This outstanding result demonstrates that informed, minimalist design can deliver top-tier efficiency. View the live performance data on Open Energy Monitor.

Alex has quite a few installations being independently monitored & achieving great results.

The Weekly Engineer Directory

Find a Master near you:

Engineer | County |

|---|---|

Bristol | |

Middlesex | |

Staffordshire |

Thanks to the Patrons

The Guild of Master Heat Engineers is supported by our Patrons.

Learn more about our Patrons here.

Podcast

The BetaTeach newsletter will at some point be discussing training as we (tax payers) are all now paying for it. If you want to understand how vocational education is set up in the UK and what is wrong with it please listen to this podcast which was recorded a few months ago.

Closing Thoughts

Alex is a real gentleman and I've had the pleasure of meeting him a few times now. It always amazes me how these younger engineers juggle their family life and work life. Often, their partners are very much involved. |  In the plant room |

What's liked about Alex is his willingness to test. Here, he chose to try the Ideal heat pump for the first time and got fantastic manufacturer support which brings me to a very important point: manufacturer support is critical but it's in a high state of flux which has never been seen before in the sector.

A Story about Manufacturer's support

I grew up watching Dad go to work as one of the 12 Technical Reps for Trianco Redfyre. Trianco, in the 70s and early 80s were the UKs boiler market leaders and manufactured oil, gas and solid fuel boilers. They were seen as the Rolls Royce of boilers back in the day and their technical reps obviously had to know what they were doing.

I was obviously very proud of dad and his technical competence and I obviously had lots of merchandise (it existed back then) with Trianco Redfyre written all over it.

Then, out of the blue the reps were all made redundant. This was seen as a good decision by the company as they wanted to save money. The boiler industry was becoming extremely competitive now that low water content and low mass boilers (wall hung boilers basically) were now becoming the norm and replacing back boilers. But it was a rubbish decision. Without good quality technical support Trianco Redfyre fell from market leaders into oblivion for many years (not to be confused with the modern day Trianco)

This story shows how important technical backup is and currently this particular component of the sector is in a major crisis: there's not enough competent technical reps in existence. This issue is compounded by the increasing number of heat pump sellers coming to market all wanting to secure technical reps. Some reps are moving about quicker than molecules at high temperature...and that's completely their choice. There's no rules that they need to stay loyal to a company. It's a space we need to watch closely as we transition heating systems.

Have a great week everyone.

Nathan

Subscribe to get more newsletters like this, if you haven’t already.